Three key points about ADAS and autonomous driving

1. Software Reliance

In the early stages of the original ADAS (Advanced Driver Assistance Systems) development, the R&D team faced significant challenges in designing a robust system. To overcome these hurdles, they developed complex software solutions. However, it quickly became apparent that pre-programmed algorithms struggled to keep up with the demands of modern automotive systems.

As the need for more advanced features like sensor fusion, visual processing, and enhanced security grew, researchers had to develop entirely new algorithms. This led to the integration of large codebases, which not only increased development costs but also introduced greater security risks. Maintaining and updating such software continuously became a major challenge for engineers.

This growing complexity forced a shift from traditional software-centric systems built on commodity hardware to custom-designed system-on-chip (SoC) solutions and hardware accelerators. These chips are optimized for performance, allowing for more efficient computation and faster response times in real-world driving scenarios. By breaking down algorithms into smaller, manageable tasks, ADAS systems can react more swiftly and accurately to dynamic environments.

The evolution of ADAS technology has set a clear path for autonomous vehicle engineering teams. It demonstrates how on-chip systems can be designed to handle highly complex tasks with near-real-time performance, making them essential for the future of self-driving vehicles.

2. Near Real-Time Design

Ensuring real-time processing is critical in autonomous driving, especially when it comes to sensor fusion and other mission-critical tasks. The development of ADAS has provided valuable lessons for autonomous pilots in managing these challenges effectively.

In the early days, ADAS developers used static random access memory (SRAMs) to facilitate communication between on-chip computing components. These SRAMs acted as output mailboxes, receiving input values for various computational tasks. However, as the number of processing elements increased, managing communication through software became increasingly complex, leading to delays in information processing.

To address these issues, ADAS chips began incorporating technologies like heterogeneous cache coherency. This allows efficient communication between different computing units—such as CPUs, GPUs, and DPUs—within the same chip, significantly improving data transfer speeds and reducing latency.

Most importantly, hardware accelerators have become central to self-driving systems, enabling on-chip communication technologies like heterogeneous cache coherency to support near-real-time embedded processing. This is especially crucial for handling complex machine learning algorithms that require fast and accurate decision-making.

3. The Challenge of Integration

The complexity of autopilot system-on-chip (SoC) designs is truly remarkable. Integrating high-performance computing, functional safety requirements, and near-real-time embedded capabilities into a single custom silicon chip presents a huge engineering challenge.

Many autonomous driving systems use hardware accelerators to perform specific tasks, such as processing high-definition radar data or computer vision tasks. These accelerators act as specialized nodes within the system, optimizing performance for particular algorithms.

In this type of SoC architecture, hardware accelerators and heterogeneous processing components can be fine-tuned for specific autopilot functions. On-chip interconnects ensure that all these components communicate efficiently and consistently, helping manage the increasing complexity of modern autonomous systems without sacrificing performance or reliability.

Welcome to OREMA's exclusive range of Front Terminal Batteries – the ideal choice for those who prioritize efficiency, space-saving design, and unwavering reliability in their power needs.

Innovative Design for Effortless Installation and Service

Our OREMA UNF series front terminal batteries redefine convenience with their integrated handles and accessible front terminal connections. Designed for seamless integration into both 19-inch and 23-inch battery cabinets, these batteries promise hassle-free installation and maintenance – a perfect fit for industrial, utility, and telecommunication settings.Advanced AGM Technology: Power, Performance, and Peace of Mind

At the heart of our OREMA UNF series lies the AGM (Absorbent Glass Mat) technology. This innovation encapsulates the electrolyte in glass fiber mats, offering enhanced performance and maintenance-free operation. Known for their high reliability and longevity, these batteries are the go-to solution for critical backup power requirements.Features of OREMA Front Terminal Storage Battery

Easy Installation & Space Efficiency: With front access terminals, our batteries simplify installation and servicing, saving you time and space.High Energy Density: Our batteries deliver superior performance while occupying less space, enhancing energy density.

Exceptional Discharging Ability: Thanks to radial grid design and tight assembly technology, these batteries excel in high-rate discharge performance.

Longer Float Service Life: Enjoy over 8 years of reliable service at 25°C, backed by unique corrosion-resistant grid alloy.

Maintenance-Free Operation: Our AGM technology ensures efficient gas recombination and eliminates the need for electrolyte maintenance.

Low Self Discharge: High purity raw materials reduce self-discharge, ensuring longevity.

Environmental & Nonpolluting: Our batteries feature Gas Recombination technology, preventing acid fog emissions.

Safe & Reliable: An efficient venting system releases excess gas and reseals valves, safeguarding against bursting.

Versatile Applications of OREMA Front Terminal AGM Battery

Our Front Terminal Batteries are designed for diverse applications including:19inch/23inch standard power supply cabinets

Communication Systems (Switches, Microwave Stations, Mobile Base Stations, Data Centers, Radio/Broadcasting Stations)

Special or LAN Power Supply Systems

Signal, Emergency Lighting, EPS & UPS Systems

Broadband, Electric Utility, Telecom, Central Office, Fire Alarms, and Security Systems

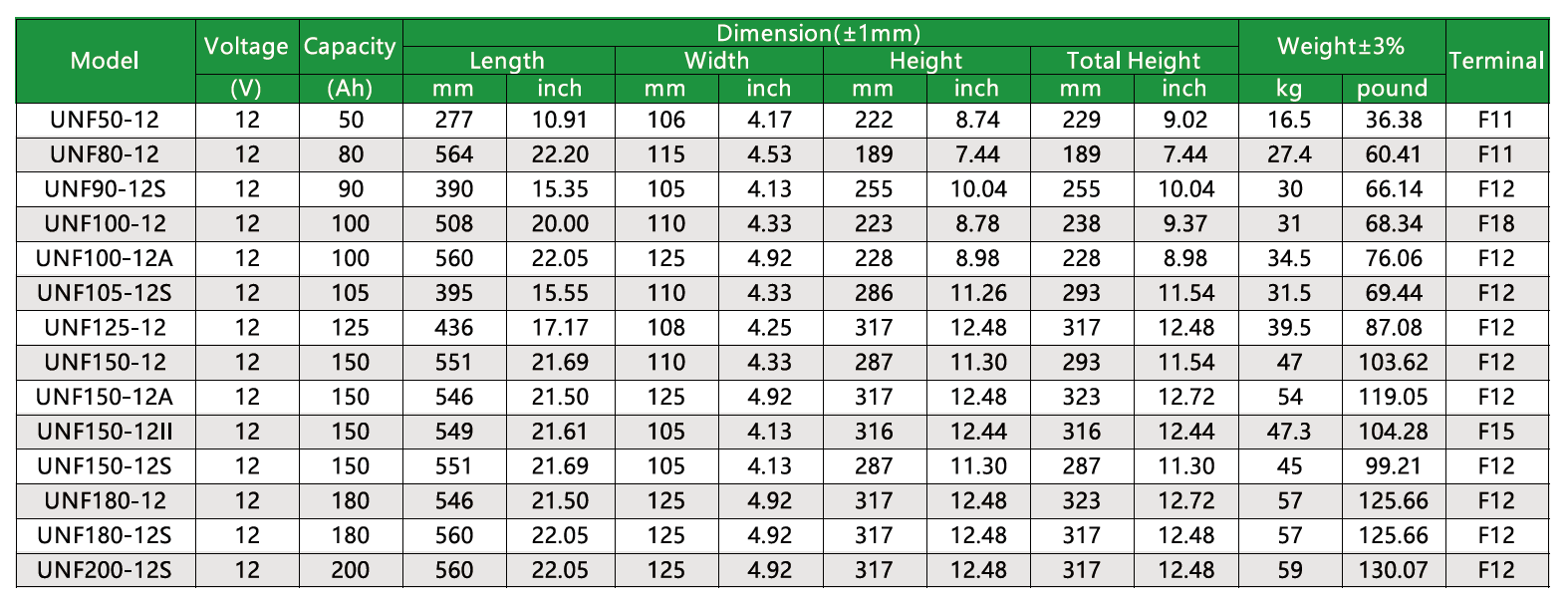

Specifications of the OREMA UNF series 12V Front Terminal Batteries:

Tailored Solutions with OREMA's Expertise

With 20 years of innovation in sealed lead-acid battery manufacturing, OREMA stands as a rising star in the industry. Our commitment to quality is unwavering, as evidenced by our comprehensive quality management system. Embracing unity, growth, trust, and quality-first ethos, our team is dedicated to providing top-tier power solutions and personalized services. Meeting and exceeding customer expectations remains our perpetual goal.

Front Terminal Batteries,front terminal sla battery,front terminal storage battery,front terminal agm battery,12V front terminal batteries

OREMA POWER CO., LTD. , https://www.oremapower.com